![]()

Good luck with nicely asking SpaceX to improve on safety. Elon, in a huff, announced months ago he’d be ditching the SpaceX Hawthorne facility in California for a new facility in Texas, with he possibly believing he can get away with flouting safety regs there. Along with labor and pay issues at the Hawthorne facility, big bad old California hurt his feelies when he was cited for numerous injuries—double the industry average; we’re talking amputations, crushed limbs, you name it. Texas would do well to keep him on a short leash and have a long one ready to lasso him in if he somehow gets away.

It would be nice if NASA could tell them to ditch the security risk who has never cared about safety or regulations in general, on top of many other problems, but for some reason everyone’s top priority was to make space stuff private rather than good. ![]()

Rich People with Big Plans donating huge gobs of money to super PACs? That’s one way of fueling politicians’ ambitions (and skewing how tax payers’ bucks get spent).

It already looks toy-like. So smooth. ![]()

This digital twin would be worthwhile if it can effectively replace Earth-bound physical simulators used to track down problems occurring in orbit.

Right? The Apollo program astronauts did it. Why not again?

(And launchpad gantries have catwalk structures built into them, but the audience numbers are quite small.)

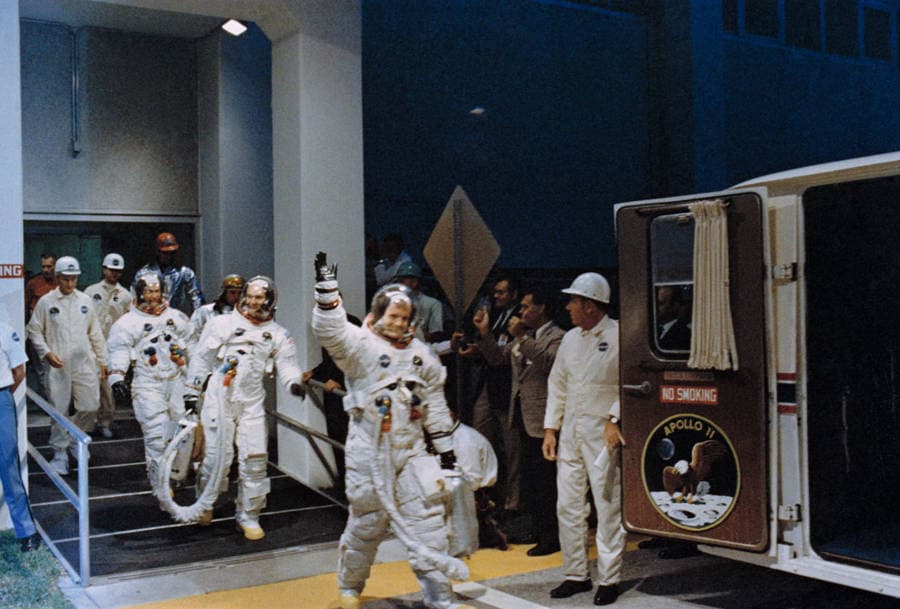

The shuttle crews walked out of the back door of the welding shack.

So happy you brought up Playtex’s ILC Dover division. I sort of doubt that Prada had anything significant to do with any truly technical aspects. Here’s ILC Dover’s work on Apollo spacesuits per Bill Ayrey’s book Lunar Outfitters:

Thermal Regulation: The suits had to protect astronauts from extreme temperatures on the Moon, which can range from -250°F to 250°F. ILC Dover developed a multi-layered insulation system to manage these temperature extremes.

Life Support Systems: Integrating a reliable life support system that could provide oxygen, remove carbon dioxide, and regulate humidity and temperature was crucial. This system had to be compact and efficient to fit within the suit.

Durability and Protection: The suits needed to be puncture-resistant and able to withstand the abrasive lunar dust. ILC Dover used advanced materials and construction techniques to ensure the suits were durable and provided adequate protection.

Pressure Maintenance: Maintaining a stable internal pressure was essential for the safety of the astronauts. The suits had to be airtight and capable of withstanding the vacuum of space.

(Lillian Kozloski’s book U.S. Space Gear is also an excellent reference, covering the history of US spacesuit development.)

![]()

1984-04-06: the STS-41C astronauts walk out of crew quarters to board the Astrovan for the ride to Launch Pad 39A.

Now all we need is a sample return mission like Scoop and round up the Wildfire team.

We’re getting to the limit of material science in all the dimensions. Superalloys, ceramics, carbon-carbon, it all dissociates at high temperatures. The best we can do is keep reengineering incremental improvements to the SR-71, and fuel usage is always going to make it uneconomical except for specialized applications. Carting billionaires around is not a big enough market. Everyone expects magic to come about, neutronium or whatever the Ironman suit is made of and whatnot. It’s not gonna happen.

<obnoxious hysterical laughter meme>

Here we go again…

I’ve already seen Moon Zero-2.

I wonder if they considered the use of sacrificial, at least one-time use, materials (while being able to achieve acceptable performance and remain well within safety margins each time). Of course, that means a lot of inter-launch servicing, but even the Space Shuttle’s reuseable Main Engines required such servicing.