Pretty cool. I couldn’t find info on what they’re made of though. Some of the stock designs are pretty strange - but you can submit your own.

Some say “out of stock.” Huh?

Pretty cool. I couldn’t find info on what they’re made of though. Some of the stock designs are pretty strange - but you can submit your own.

Some say “out of stock.” Huh?

The first 3D printing I encountered in the real world was at a design exhibition, a woman had developed a way of printing a shell for a shoe in a firm, but flexible, plastic with a much softer interior to provide the precise fit.

Or

I found this video article quite interesting. This sounds like an interesting way to save material cost when printing complex prototypes.

(of course, it needs a special printer so…)

Eventually I want to have a building with a watch repair shop. It will need a sign out front.

I printed an earlier version, but haven’t painted it yet. But by using a color 3d printer I won’t have to. Those numbers end up pretty small.

How about “Jelena Dmitrijewna’s Watch Repairs & Art Gallery”?

I looked her up on Wikipedia and discovered that she is an Israeli classical pianist. Perhaps “Watch and Piano Repair.” So what is your reasoning for the name?

Being married to Dali must have been interesting.

And then some.

Eventually (if they don’t die), they get large enough and start blooming. If she has multiples, she’ll pick her favorite and then choose a pot to transfer them to. She has some store-bought pots, but increasingly she has been asking me to print custom ones. The majority of the pots that I print have come from a single designer on Printables, SASSy Design.

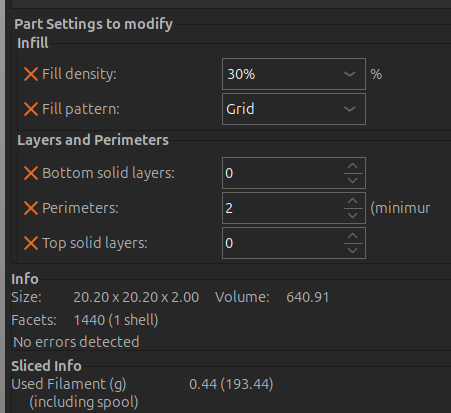

I make a few modifications before printing. First, I (proportionally) size the pot to her specifications. She’s mostly settled on a few diameters between 50 and 100mm, but there are occasional outliers. Second, I add a drain and a hole for the wick. I’ve found that doing this in the slicer works well. The drain is created by modifier(with no top/bottom, all infill) in a cylinder shape 20mm wide at the bottom center of the pot. The wick hole is created by adding a small negative volume cylinder at the center of that. Unfortunately, due to limitations in PrusaSlicer, I can’t include those features in a Vase mode print. Or rather, I can’t include a modifier shape because vase mode has no infill. To work around this, I created a drain disc which is just a disc shape made almost entirely out of infill, with a hole in the middle for a wick. I make a matching indentation in the vase/pot, with a smaller hole at the bottom so that it’s held in place, and then print them separately.

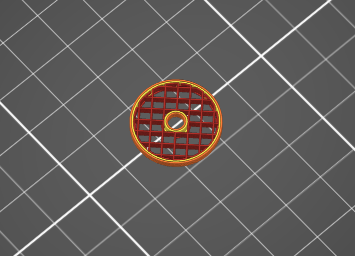

The disc ends up looking like this in the slicer:

It uses less than 0.5g of filament, and takes about 5 minutes to print.

It looks like this after printing:

This is the Dragon Scales pot in (I think) Mika3D Gold Silk PLA, which I’ve had for 5+ years at this point, so it’s not exactly in tip-top shape, but still prints well enough for this purpose.

Here it is with a violet in it:

If you look closely, you may see that there are a few places where the layer alignment seems off. That ended up being due to the plugin (Octolapse) I was using for timelapse videos. It would move the print head out of the way after each layer, take a picture, and then assemble those pictures into a video at the end. It’s a fun artifact you can get with each print, but with Vase mode it was causing issues. My best guess is that since it prints in a continuous spiral, there are less obvious layer boundaries, and moving the extruder out of the way was causing slight misalignment when resuming. Turning off the plugin completely eliminated the issue.

I’ll probably post pictures of other pots printed this way over time, as I remember to. I’ve also got a project coming up to build a (not 3D printed) shelf for storing my filament, as it’s gotten out of hand, and my Core One is still sitting in its box, waiting to be assembled and put into service, so I’ll probably post something about that at some point too.

Neat!

I love African violets, i had a few but after those died i have not replaced them. I should replace them.

And the 3D pot looks neat! Would it be possible to set it up where you can turn it into a silicone mold and use concrete to make a batch of plant pots? ![]()

As noted above, she frequently has duplicates, and is constantly asking me if I have anyone she can give them to. If anyone is sufficiently close, I’d be happy to bring them some. I’m not sure how easily or well they would ship, but it’s not out of the question.

Probably, using some form of Lost Wax casting. Here’s an example with metal: