Our local library has a 3D printer and offers classes.

You might check if your local library or community center had something similar.

That depends a lot on how you go about it. There are a lot of free options like Blender, Tinkercad, FreeCAD, etc. I personally lean towards OpenSCAD, but that’s because I’m a weirdo who thinks better in Constructive Solid Geometry and struggle with getting exactly what I want out of more normal modelling software.

It does look like one of the local libraries has an intro to 3D printing but it’s during the work week and its the one library smack dab in the middle of downtown Austin. Which makes it a huge hassle for me, but i’ve bookmarked their classes page to keep an eye on future opportunities.

Nowadays 3D printing is much more accessible than before. If we except the Voron project printers (basically the drag racecars of 3d printing) all printers for sale nowadays are orders of magnitude easier to set up than 10 years ago. If you’re willing to spend some money – and sacrifice a bit of freedom, bambulab offers are almost literally unpack and start printing.

As for modeling there is quite a bit of software catering to many levels. Many of the more accessible and popular ones are web or subscription based, but the open-source offers are getting better. I learned to use freecad from scratch in two weeks just watching YouTube tutorials (I had previous experience with rhinoceros but is a completely different beast). And freecad has improved quite a lot in the. Three years I’ve been using it.

I usually won’t say things like “this is the best moment to start”… But is quite a good moment. Printers are way cheaper, but still not comodditized enough to be feasible to close source them without users raising hell. Improvements are still happening but they are not as dramatic as five years ago (printers are getting faster, but not 400-1000% faster, print quality is better but nowadays improvement has a lot to do with materials, so everyone benefits, etc)

YouTube has a lot of good channels but I will have to post them tomorrow. Not getting out of bed to compile a list of resources ![]()

It wasn’t a decision I took lightly, but my current printer has been busy almost constantly, and my backlog only seems to be growing, so effectively doubling my output was something I could justify. I mostly like Prusa as a company, similar to Framework, so it didn’t make sense to me to shop around. With a different set of constraints, I’d probably make different choices.

The XL is very cool. If I was running a commercial print farm, I think I could maybe justify having one or more of them, but when you can get 3-5 MK4S or Core Ones for the same price, it just doesn’t make sense. So far I haven’t run into anything that the build volume of my current printer has been a hindrance for, but there are obviously specialized situations where it would be useful.

I think if you want to create more artistic or organic models, then Blender is a good choice for that type of work. There are lots of tutorials with many different specialties, many of them free. On the commercial side, I’ve seen reference to ZBrush, but I can only imagine choosing that if you were doing commercial work and could justify the price ($400/year).

If you’re trying to create functional or mechanical models, then a CAD program is probably more reasonable. I haven’t used Tinkercad, but it looks very beginner friendly, and is from a company(Autodesk) with a long history in the space. Their other popular offering is Fusion (360?) which is much more professional focused. It’s also subscription software, and very expensive in my opinion. There is a non-commercial license available for free as well. I have used it briefly to customize a few models, but didn’t find it particularly well suited for that purpose, although part of my problems were due to me struggling (and mostly failing) to get it running on Linux. Some of the YouTube channels I watch seem to prefer Solidworks, but I include it here mostly for completeness. I’m sure there are others.

The three that I’ve used for this purpose are as follows:

Here’s a (not very) brief overview of the process of creating my first (and so far only) 3D printed thing from scratch.

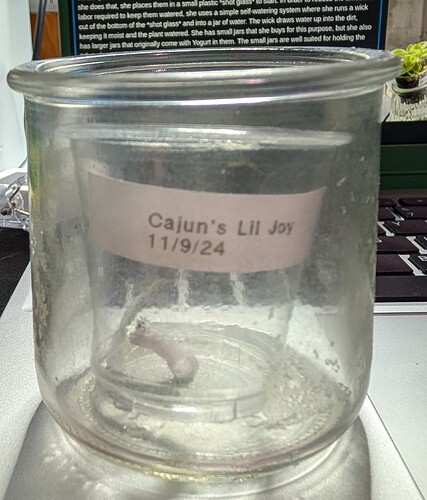

My wife grows African Violets. She grows a lot of them. I think she may have over 200 of them at the moment. Once a plant grows past a certain point, she is sometimes able to take a part of that plant and use it to create a new plant. When she does that, she places them in a small plastic shot glass to start. In order to reduce the amount of labor required to keep them watered, she uses a simple self-watering system where she runs a wick out of the bottom of the shot glass and into a jar of water. The wick draws water up into the dirt, keeping it moist and the plant watered. She has small jars that she buys for this purpose, but she also has larger jars that originally come with Yogurt in them. The small jars are well suited for holding the shot glass in place above the water, but the large jars are not.

Here’s what they look like:

The four starting from the left in front and the two starting from the left in back are in the aforementioned small jars, and the remaining three are in the larger jars. It’s not an illusion, the plants in the larger jars are also in larger cups, which you can see are barely larger than the rim of the jar at the top, which also limits how much water can be stored below. The small shot glass cups don’t fit in the larger jars at all:

Or rather, the fit completely, which makes the jar unsuitable as a water reservoir for that size cup.

All of this is to say that I have a 3D printer, so I should be able to print something to solve this! It should be a fairly straightforward solution, I just need a disc that sits on the rim of the jar, and has a hole in it which is large enough to hold the small cup above the water. Because I am also a weirdo and have effectively zero 3D modelling experience but can write code, my first attempts are in OpenSCAD.

Here’s the code the generates the jar adapter:

difference() {

union() {

lid();

insert();

}

hole();

}

module lid() {

translate([0,0,5]){

color("Green") cylinder(5,33,33, center = true);

}

}

module insert() {

color("Blue") cylinder(5,27.5, 27.5, center = true);

}

module hole() {

translate([0,0,0]){

color("Black") cylinder(20, 22.5, 22.5, center = true);

}

}

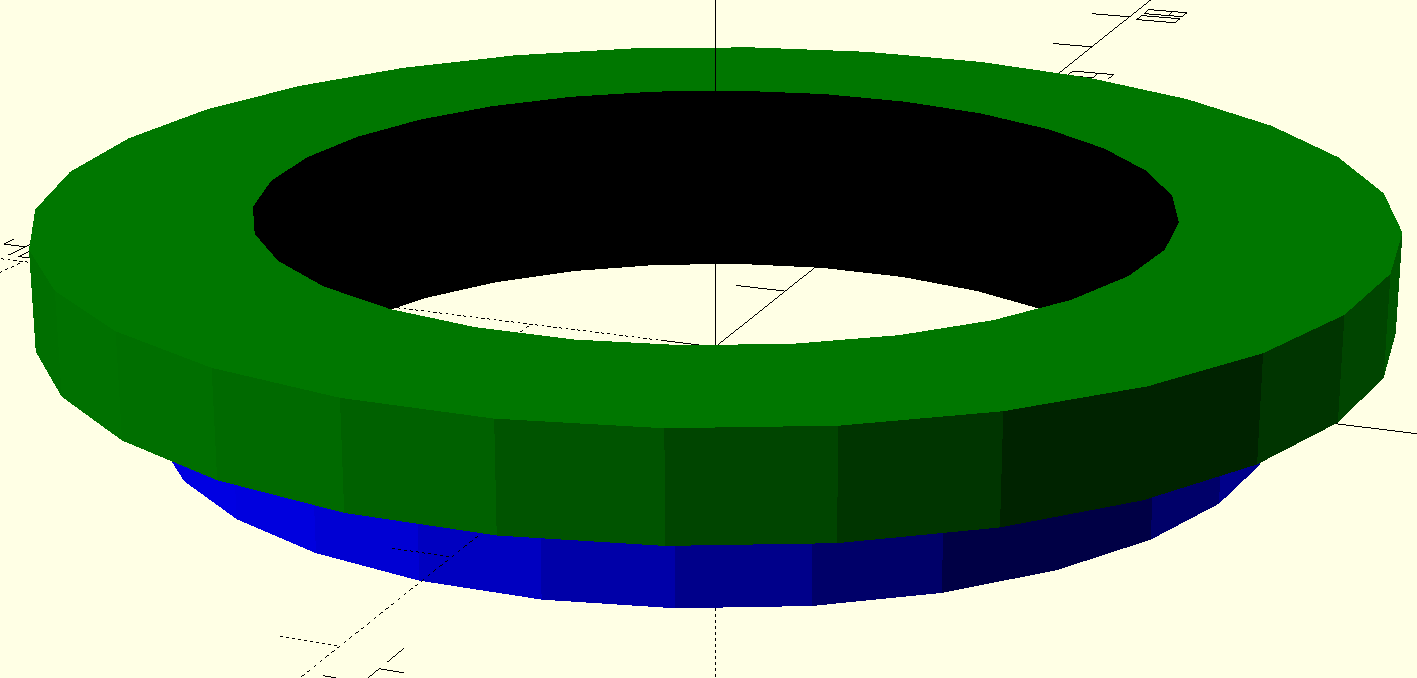

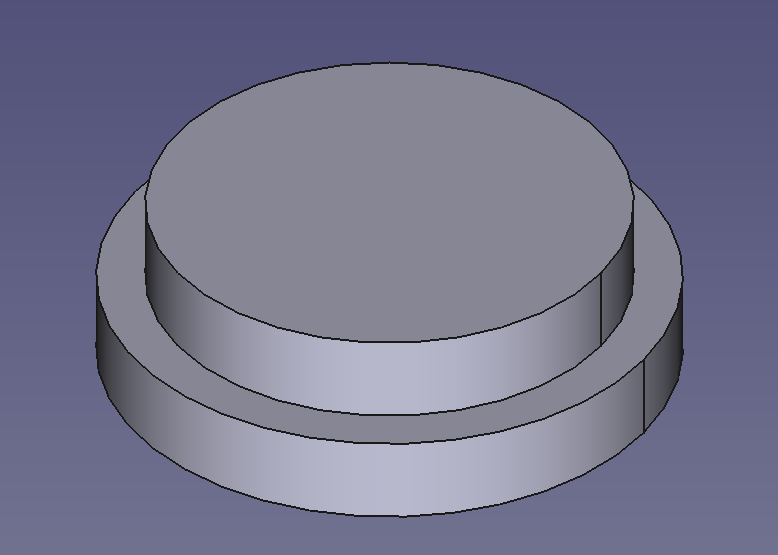

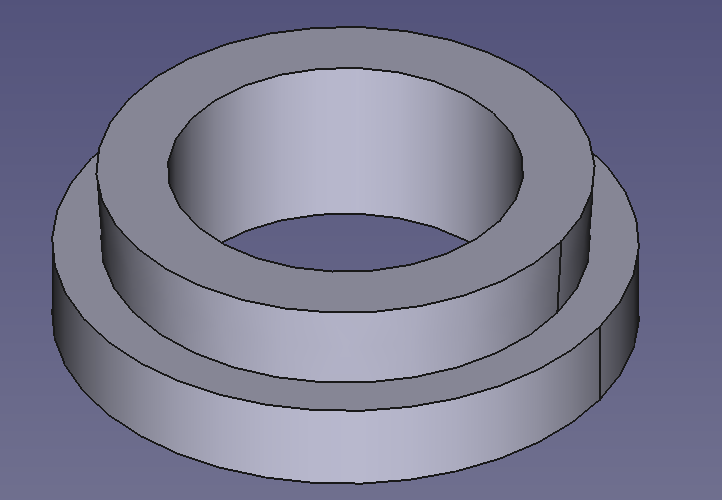

That ~22 lines of code generates this model:

It’s three cylinders: one for the lid (in green), one for the insert (in blue), and then one for the hole through both of them (in black).

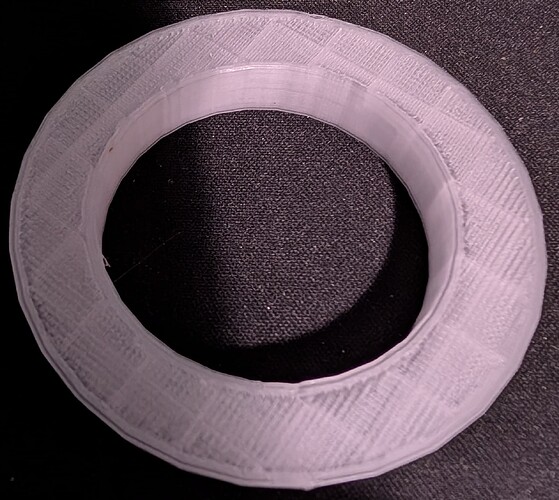

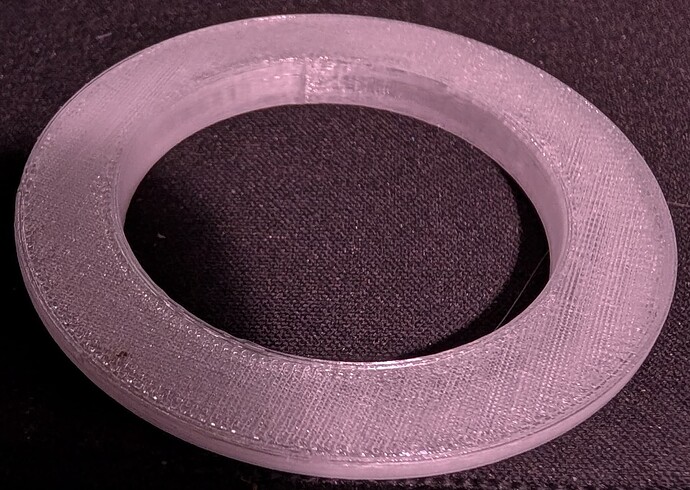

Exporting that model as an STL and then slicing it and printing it(upside down) produces this:

After tweaking the infill and print settings a bit, I get it down to ~8g of filament and printing in ~30m on my then MK3S (~15m on my upgraded MK3.9S).

Pros:

- It works.

- I made it with code.

- It’s relatively easy to modify.

Cons: - It’s not perfectly round.

- It may not be obvious in the photo, but it should be clear in the screenshot that it is faceted. It’s not a printing issue, but rather how OpenSCAD seems to generate cylinders by default.

- The workflow of modifying the code, generating the model, exporting it to STL, then slicing and printing it isn’t as smooth as I’d like it to be.

Sometime later, while I was working on printing planters, I started working with some of the basic modelling features of PrusaSlicer, and realized that I could probably generate this adapter directly in the slicer, no OpenSCAD necessary. So that’s what I did.

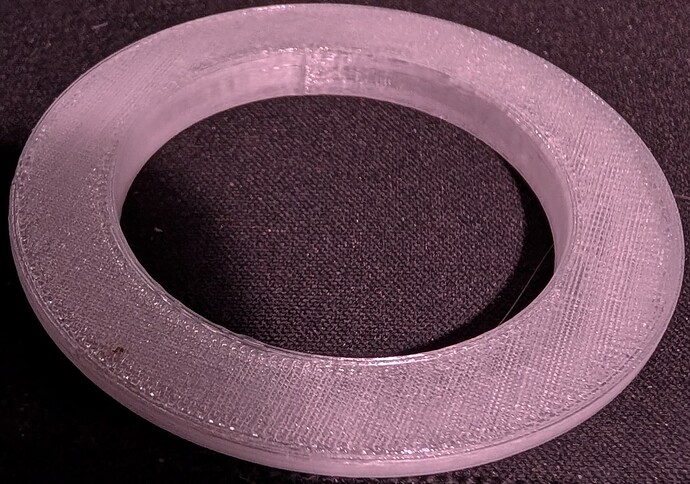

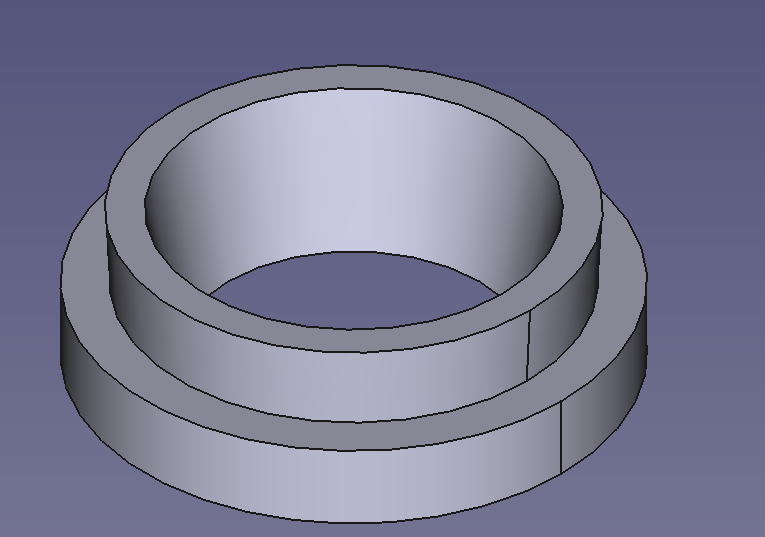

Using a similar setup with two cylinders stacked on top of each other, and then a negative volume cylinder to make a hole in them, I created this:

It’s functionally identical to the first one, but rounder and smoother.

I went through a few more iterations:

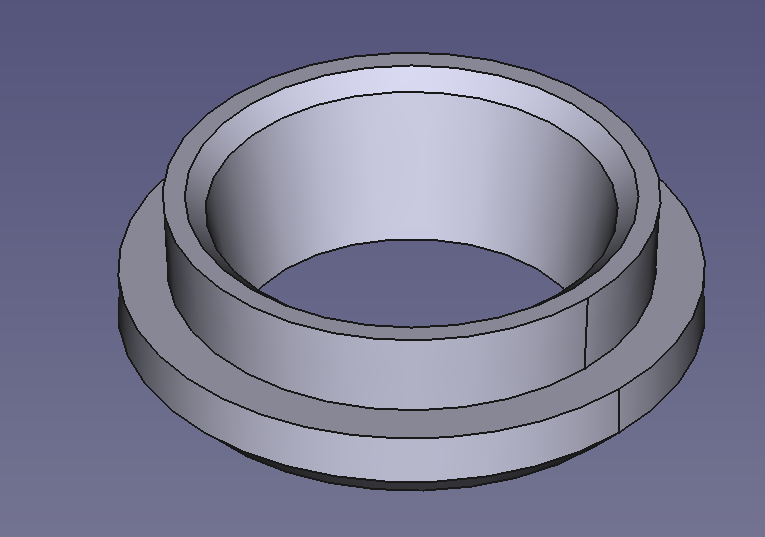

I tried reducing the height of both the lid and the insert, but that ended up with an adapter that didn’t have as good of a grip, so I finally settled on this:

This version keeps the thin lid, but restores a deeper insert so that it grips the inside of the jar effectively. With similar print and infill settings to the first version, it can print in under 10m with ~6g of filament.

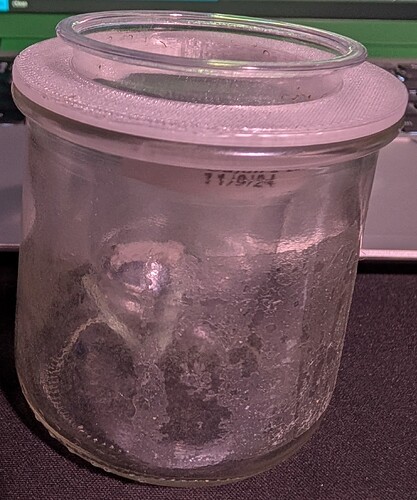

Here’s what it looks like in action:

Pros:

- Easy to modify.

- Rounder.

- Uses less filament.

- Prints faster

Cons: - Less precise editing.

- Not universally shareable.

I’ve been spending a little bit of time learning FreeCAD lately, so I think I’ll try my hand at recreating this again and seeing the advantages and disadvantages of that approach. I’ll report back on that later.

It’s also worth looking into maker/hackerspaces in the area. Here’s a quick search that turned up three around Austin:

https://makerspacedir.com/?select=&lp_s_loc=austin%2C+tx&lp_s_tag=&lp_s_cat=&s=home&post_type=listing

Wierdos unite! ![]()

Honestly, I think the main reason I lean that way is because my earliest 3d modelling experience was with POV-ray, which was a similar thought process. I was also working with more normal (and much more expensive) cad software for drafting at the time, but haven’t quite connected the processes…

Which may be to say, it’s worth it to try several of them and do some tutorials, with an eye towards an engaging project.

On freecad the process would be like this

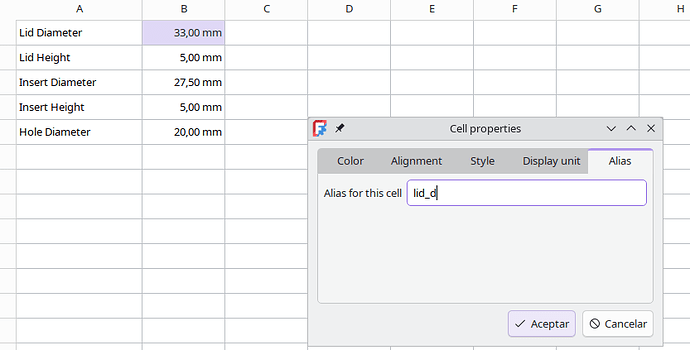

(Optional) Step 0: Write down the measures

So, this can be skipped if you think you won’t need to tweak the piece a lot, or is a one-off, but one of the nifty features of FreeCAD is that, as the models are based on plans, you can commit some of the plans measures into a spreadsheet. As I’m not sure of the measures you use, I’ll do that.

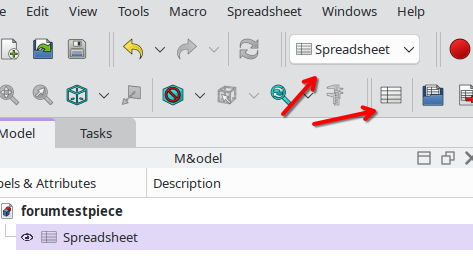

I select the Spreadsheet “bench”, and click on “new spreadsheet”.

I Input the data. With this we could already use it, but then we need to reference them by Coordinate (as in Spreadsheet.B1).

Instead of that, I can right-click on each cell, go to properties and assign an alias. Again, this is not needed, just makes easier to modify the model after.

Step 1: Make the model

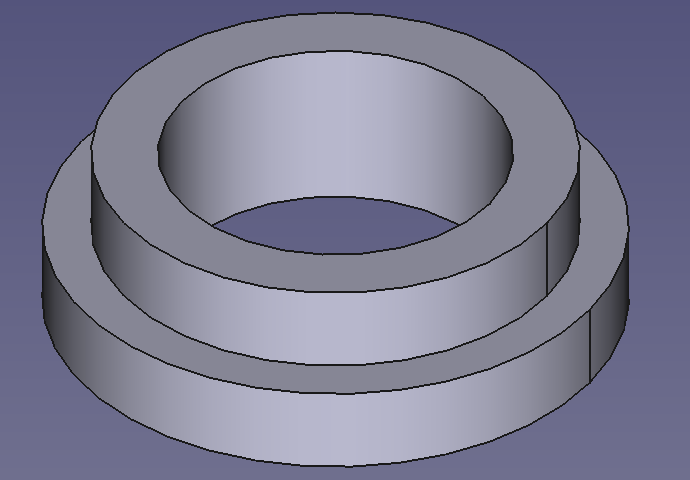

FreeCad uses an additive-substractive model that favors pieces that overlap, so I’m going to build this upside down (which is how we are going to print it, anyway). This model will be composed of two cilinder primitives (the lid and insert), and one substractive primitive (the hole). For more complex designs we would have used sketches, but this is not the day ![]()

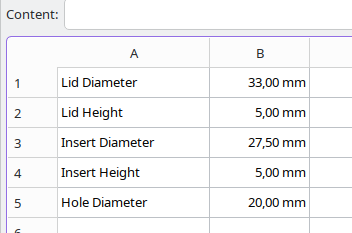

We select the bench “Part Design” (basically the one you’ll be using normally) and click on “Create Body”.

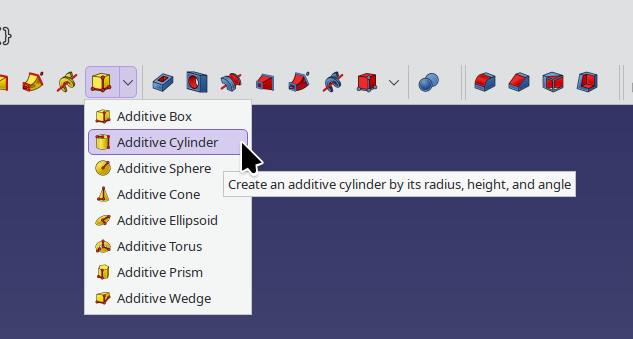

We click on “Additive primitives” and select “Additive Cylinder”

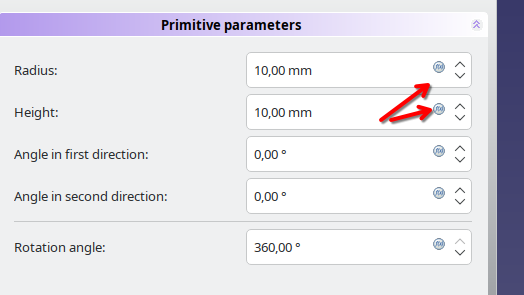

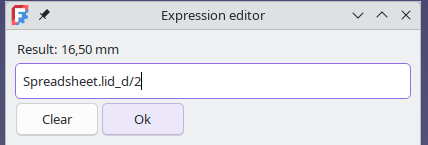

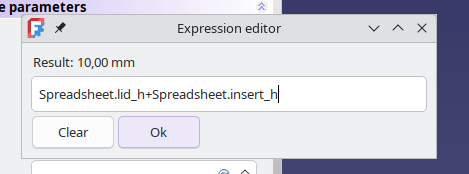

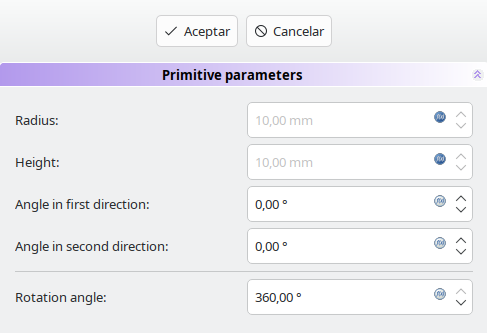

We can input the information directly, but as we saved the data on our spreadsheet, we need to click on the “formula/expression” button.

As I wrote it as diameter, but the cilinder generator expects radius, I divide my value in two.

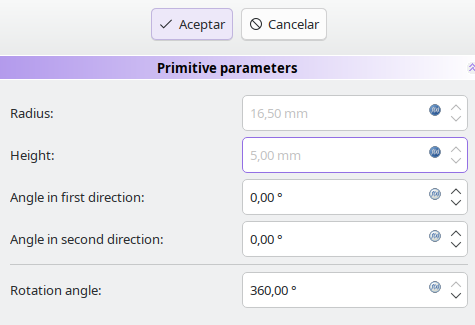

Note that the parameters that are generated using an expression are greyed out so we cannot change them manually from here.

We repeat the process for the second cilinder.

For the insert, as FreeCAD prefers overlapping models, I’m going to generate it from the bottom, but make the height equals to the height of both the lid and the insert.

So far so good.

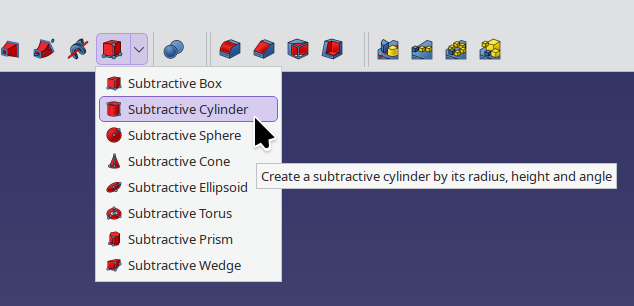

For the hole, we need to click on “substractive primitives” then select “Substractive Cylinder”

The formula for the height is the same as the one used in the insert. If I was doing this manually, I would add some margin in the bottom and the top (like 1mm on both sides) but this should be fine.

The “finished element”

Step 2 DFM

Here is the part where I usually add some finishing touches using the “Fillet”, “Chamfer”, “Draft” and “Thicken” tools to fine tune the design for printing.

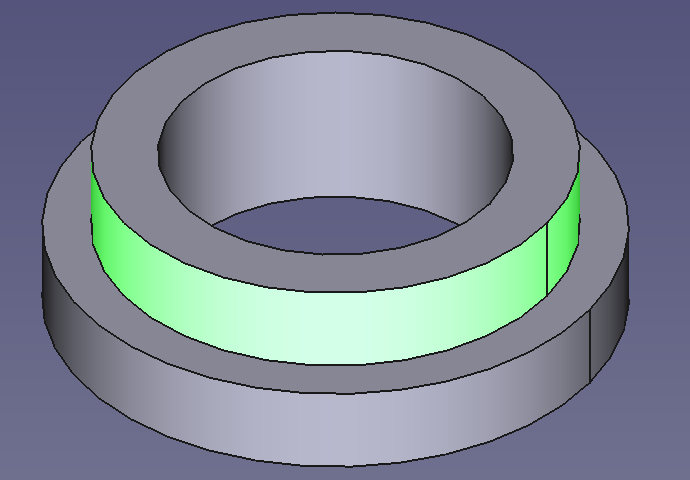

For example, we could add a bit of Draft to the exterior wall so it grips against the wall better, playing with the elastic tolerances of PLA. To do that I click on the exterior wall

And select “Draft”

FreeCAD is usually good at figuring out the orientation of the wall, but you can click on “Neutral plane” and select the wall you want your draft to grow or reduce against.

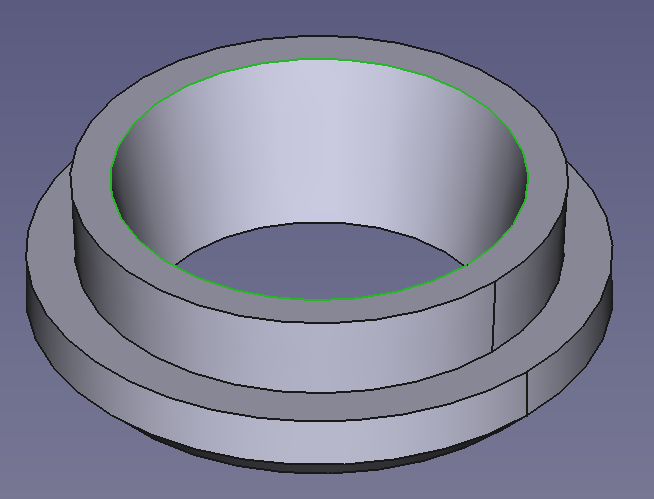

Here’s with a draft of 3º.

We also don’t need that much material on the insert --again assuming the insert needs to grip the exterior wall, not the interior – so I’m going to draft the walls to make them thinner towards the bottom (top on the model).

And I’m going to add some (2mm) chamfers on the lid (3D printers are not very good at rounded fillets so is better to keep it 45 degrees if you care about print quality) and the upper part of the insert (1mm).

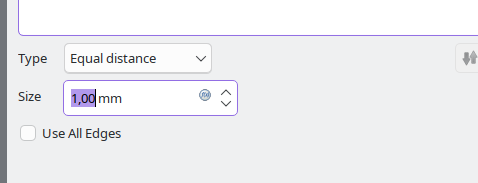

To create a chamfer you select the border between two faces.

And then click on “Chamfer”

Usually the default “equal distance” is good, and you only need to change the size. but sometimes you want a fillet in an specific angle or of a specific depth, and there are options for that too.

And the finished model, that can be exported into your favourite slicer.

And here you can download the file I made so you can examine, print or modify it at your leisure ![]()

Most of the stuff I print are found models on the usual repositories (Thingiverse, Printables, MakerWorld, etc.) but I’ve designed a few things using TinkerCAD- It’s absolutely a “Baby’s first 3d modeling” application and it has some serious limitations, but for the utilitarian stuff I’ve done up (brackets primarily, but that biohazard sign was something I did as well) it works well enough.

I started with a PrintrBot Simple Metal (RIP to both the company and the machine), went to an ill-advised purchase of a very flaky dual head Flashforge Dreamer that had most of the controller boards and servo boards flake out on it, a Creality CR-6SE (basically an Ender3 with a number of quality of life upgrades) and my current hotness, a Bambu Lab X1C with AMS, which is going to have the Hydra mod installed in it at some point soon.

I would love to have a fully kitted out Prusa XL, but at nearly $5000 with shipping, that’s well outside my range, and while Prusa’s quality and support is very good (they did make the first good commercial quality printer born of the RepRap project), even getting the kit version is still too much for me. (it essentially knocks the shipping cost down, but then I get to spend a day putting it together and munching on the XL bag of gummies they include with it. ![]() )

)

For a rank beginner to the hobby, I’d suggest an A1 mini or an A1 from Bambu Labs, questionable recent actions aside- It’s a bed slinger with access to the same model infrastructure and about 90% of the capabilities of the P1 / X1 series at a fraction of the cost. And if you do upgrade to one of the CoreXY style models later on, it makes for a good secondary machine.

Creality’s claim to fame is the sheer number of variations on the i3 style bed slinger they have- even the Ender 3 which put them on the map, has multiple versions of it, and they sell all of them, so it’s a little confusing if you don’t know exactly what you want. Creality also has QC issues, so their printers range from ‘works out of the box’ to ‘needs tweaks to make work right’, down to ‘caught fire when I plugged it in’. (the first batch of CR-6 units had that, and I ended up re-building the power inlet system on mine when it’s power switch blew out on me.)

Indeed- a number of people are still ranting and frothing at the mouth over Bambu Labs pulling a “I am altering the deal- pray I don’t alter it further” move last month. Me, after dealing with the printrbot’s handful of upgrades and sudden demise (can’t replace the hot end if the company making them has died…) and the headache that was the Flashforge, I wanted a printer that was an actual tool and not a hobby unto itself. That’s why I went with the X1C- by and large, the only thing I’ve had to do with it is clear a few jams on the AMS side and I’m due to give it some maintenance.

That’s good. But for me – and many other people – the lockdown is a prelude to suscription. You don’t make a local printer force to authenticate online if you don’t plan to further lock it down.

Qidi for me seems a better proposition and fills more or less the same niche, with ready to go hardware¹ coupled with open source software, so even if they go under, the community should be able to take over, assuming there’s enough traction for that.

Creality is a good option on the low end market. The Ender 3 is basically the standard everyone copied (technically itself was a copy of the prusa, but I digress), so is easy to find parts, and the old V1 model can be found as low as 99$! Though I personally recommend buying one that has autolevelling, for convenience. I don’t really like much the Creality K1C. Had one briefly and did found it small and noisy, so I cannot opine on the new CoreXY.

Anycubic used to be really good, one of the first to offer ready to print systems. I still have a Vyper, which basically was a fully kitted out Ender 3, that assembled by putting two screws and connecting the printer, and it was… like 280$. Slow for today’s standard but it required little calibration to get good prints. Unfortunately, their new platform from where they run the new printers is propietary and tied to their cloud so I cannot recommend them anymore.

I’ve heard a lot of great things about Sovol, but i have the feeling this is more like an oldschool company: printer will be okay, but you will need to tinker with it for it to be great.

Unless you love “projects”, stay away from Vorons. They are really amazing machines is like 40% tinkering/60% printing (the first two weeks 99% tinkering). Vorons are like F1, you don’t want one as your daily commute, but you can appreciate what they’ve done for the community in general, as the more useful voron developments eventually trickle down to the consumers.

There are many more brands, like Flashforge, and Elegoo but I haven’t done much research on them because they tend not to be really accessible in europe (or they are just outside of my price range), so I don’t have a strong opinion for or against them.

In short, Bambu did a great job waking up the manufacturers, but right now I would not buy one unless they really clarify their position. Otherwise I will treat it as any other “industry focused printer”: something that will require not only purchase of the printer but an ongoin maintenance that will not be handled by me… and that I cannot afford to ![]()

¹ There has been a serious bug in the 110V of the Qidi plus4 but the system is quite modular and a replacement part was sent to all the buyers.

I wanted to say that even the DIY printers are nowadays generations apart from what you could buy 5 years ago. Case in point:

This is a relatively simple build that you can assemble with mostly off the shelf parts. Is at least twice as fast as my Vyper, and 100 times as fast as my first printer – a reprap.

Not saying is a good “first printer” but I would have loved to have this as my first printer.

The comments above on 3D printers makes me scared to get one! I think I’ll stick to services like Shapeways. It’s hard enough just trying to wrestle with Blender.

I did a fair amount of modeling at work (retired now thank goodness) using a program called GAMBIT. It was part of an industry computational fluid dynamics package called FIDAP (now Ansys FLUENT, last I heard) that was subscription and very expensive. I used it only for fluid flow simulations, back before 3D printers (and then toward the evolution of them). This was the late 1990’s until about 2010. We switched to a more modern program after that.

And now we have free CAD programs. Somehow I heard about Blender maybe 8 or so years ago, so got into that. Quite a steep learning curve and not the best interface, but it works.

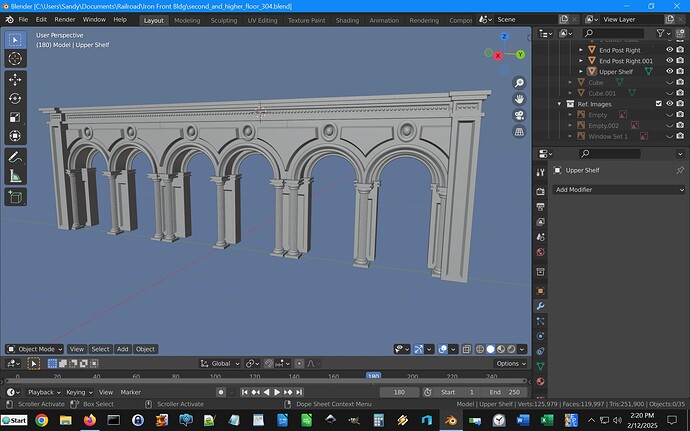

My latest project is an “iron front” style building. Note this is only the front; I have some commercial plastic brick sheets I can use for the sides. Here’s a photo of a real building in this style:

I don’t think I’ll bother with the bay windows at the top.

It’s very ornate, but the good thing is that it’s a lot of repeated elements, perfect for copy and paste functions. I can’t imagine being an architect/draftsman back then and having to draw the same thing over and over (though in my naivety maybe draftsmen could somehow copy and paste too).

Anyway here is one floor of the building I created in Blender, though somewhat simplified and incomplete.

One thing I don’t like about Blender is the mix of keystrokes and mouse actions needed to do anything. I don’t know half of what you can do with interface to make it easier; I’d have to look at a lot of YouTube videos and trial and error to figure all that out. What I do know is good enough.

Got it moving today

Amazing!

I’m not a Blender expert by any stretch of the imagination, but it might be worth looking into how to use geometry nodes.

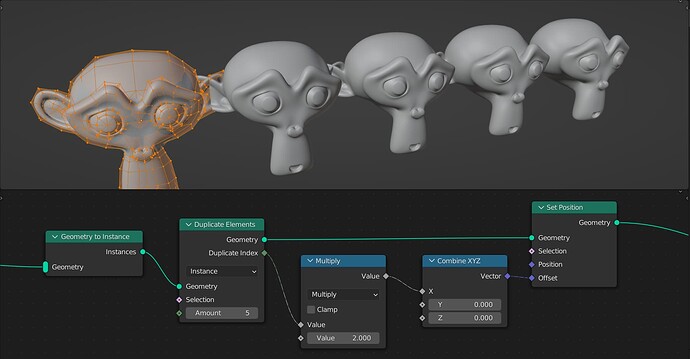

Here’s an example from the documentation:

https://docs.blender.org/manual/en/3.2/modeling/geometry_nodes/geometry/duplicate_elements.html

By combining a few nodes, they were able to create an arbitrary number of duplicates offset consistently. I think this should make it possible to edit one, and all of the duplicates are automatically updated, no copy/paste necessary. In your project, it should be possible to repeat the arches (or pairs, as it appears) horizontally, and then use the output of that combined with the sides to generate a floor, which you can duplicate vertically and then combine that with a few other things to be able to generate buildings of arbitrary height and width. You could probably even take it further and create nodes that generate the pieces of the arch, etc. so that you can assemble the whole thing programmatically out of parts. Remember, I’m a weirdo, so everything looks like parts that I want to program…

I had no idea you could do that. Looks a lot easier than what I do.

I’m pretty sure geometry nodes are a fairly recent addition to Blender, but they’re very powerful.

Here’s a possibly relevant tutorial:

Again, I’m not an expert. My daughter has expressed interest in learning Blender, and this channel is one that I found while looking for tutorials.