Rock-solid stable, but also easily removable if I decide to alter or upgrade it: the plinth box is tacked to the skirting board with just a bead of silicon, same again for the connection between plinth box and cabinet, and the cabinet is held to the wall with a single screw.

You are a regular Harrison Ford.

wow, it even matches the walls! it’s beautiful.

I spent all day working on a project for Donald Trump.

On one of your in-process pics I was going to ask why you went with the horizontal grain on the doors, but now it has become clear!  Very nice!

Very nice!

In that theme, a catalog of imperfections…

I didn’t cut the half-laps for the door crossbrace quite deep enough or clamp them well enough. As a result, the crossbrace forces the plywood out a bit, creating a small gap between it and the frame:

I made a complete hash of the magnetic latch installation. Initially, I drilled holes to sink both flush with the wood, but (a) the holes were slightly misaligned, and (b) one or both needed to be a little bit proud in order to make contact. Installing one magnet and then using it to align the other turned out to be the key.

Alternately, I could’ve just used one magnet plus an oversized piece of steel, making the whole precise alignment thing unnecessary.

If I were doing it again, I would probably add some sort of thin face veneer to cover the frame joinery when the door is open. Lap joints aren’t that pretty.

There are a few spots that would have benefited from a bit of sanding pre-varnish.

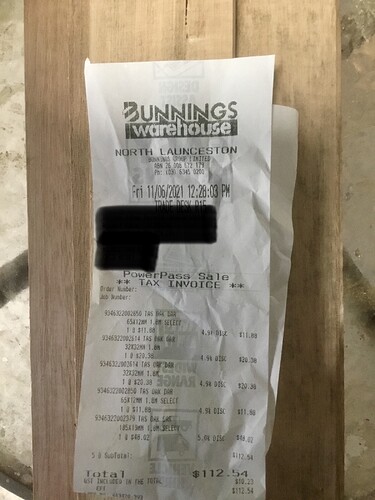

When I first bought my wood, I got four 3m lengths of pine for the frame. Four 1.6m verticals, and four 1.4m cutoffs to make the eight 0.6m crossbraces.

And then I went and cut four of the crossbraces from one 3m length, leaving me with only three long pieces for the verticals.

So, I hurriedly went out and bought another 3m length of the same dimensions. But I wasn’t paying attention, so I accidently grabbed a length of tasmanian oak instead of pine. Which (a) costs three times as much, and (b) doesn’t match in colour or hardness.

But never mind, it doesn’t show from outside.

Although I like the way it echoes and camouflages against the structure of the wall, if doing it again I might have replaced the trim strips and doorframe with a dark-coloured contrasting wood. Maybe some nice Tasmanian hardwood. I also should’ve just bought thin square strips and moulded them myself rather than paying for premade mouldings; it would’ve been cheaper.

The mitre joints on the doorframe corners are a bit rough:

When building, it’s common to add small pencil marks to keep note of the orientation of parts. For example, you might write “T” on something to mark the top. The idea is to later remove these marks with an eraser or sandpaper before varnishing.

Oops:

But, as I said:

I’ve spent all day working in a project for Kushner.

It’s an 8-page book with 2 pages of data, and this has been going on since last night. And now they think the data might be totally wrong.

You poor thing.

This would fit well in the Olds/Tech thread.

I have a lot of antique hand tools that were my grandfather’s and my father’s. I used to be fascinated by the brace-and-bit. And planes; there’s something soothing about using those.

One of the grannies at the craft store has asked me to make her a small writing desk.

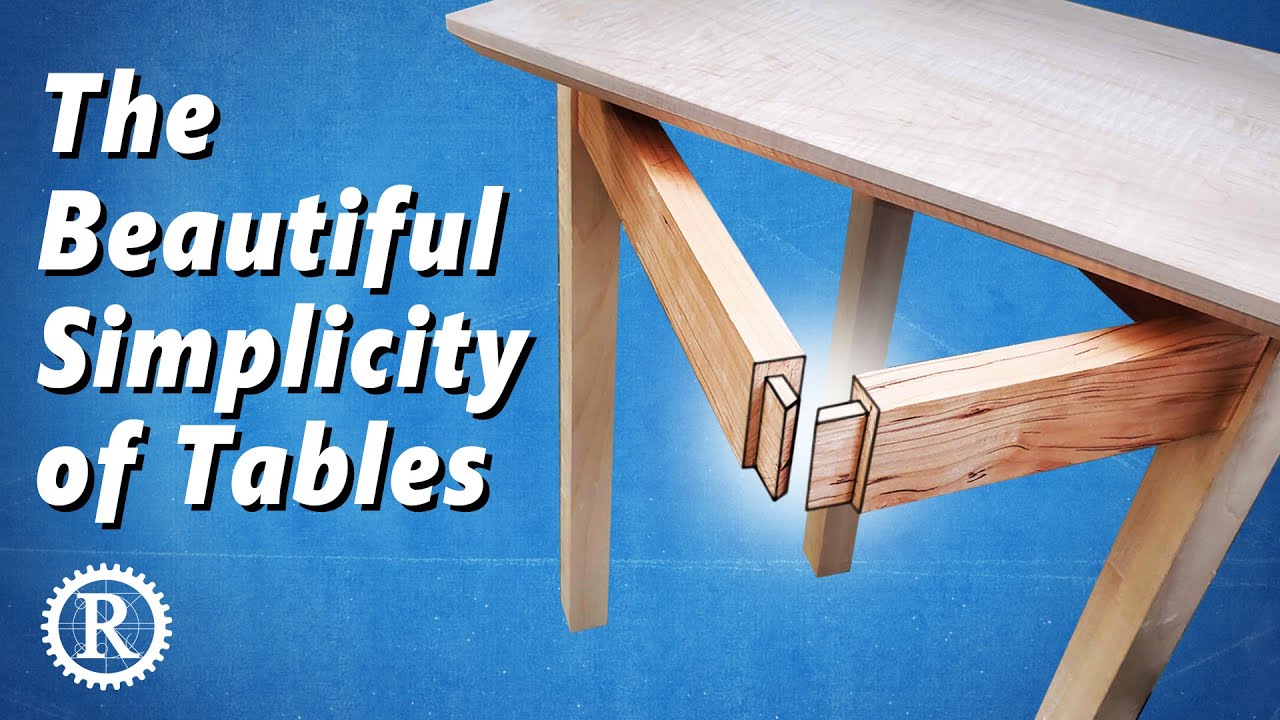

I’m going to make it from Tasmanian Oak, loosely based on this design:

Gonna be 900mm wide by 400mm deep, about 750mm tall. Just gotta wait for a non-stormy day to make a run to the timber yard.

How it started…

How it’s going…

Handle is from a branch off my red maple that has been in my garage for four or five years.

Mallet is likely ash as it is obviously beetle chewed that I picked up off the side of road.

Danish oil finish since that was the can I grabbed

I’ve got two black walnut trees in my yard. Great stuff.

Nice.

—

Ever tried using a round carpenter’s mallet?

They’re great for tapping chisels at odd and constantly-changing angles (because there’s no need to realign the striking face), and are simple enough to make that you could knock one out even on an improvised powerdrill lathe or unpowered pole lathe.

You just need a toolrest, a spike at each end and some way to make it spin a bit.

I want a lathe of some sort, but I lack the space.

My improvised attempts at lathing have never turned out well.

Lack of space is a bummer. Have I mentioned that I’m planning on building a third shed?

If you ain’t got room you ain’t got room, but: at the smaller end of the wood lathe market, you can still get useful work done with something that requires only a couple of square feet of benchspace.

The main use of big lathes is for long spindle work; table legs and walking sticks and so on. For normal sized bowls/doorknobs/toolhandles/etc, you only need a very short bed.

I’ve considered that size, but I’d need to find my workbench again.

Which is what I started out doing today before getting sidetracked on some mallet thing.

Whose did you use and are you happy with it?