I think he’s in his element, though.

Time for varnish, varnish and more varnish.

Unfortunately, it’s <10°C and raining down here at the moment, so there’s no chance of trying to hurry it along by sneaking in two coats a day. I can’t do anything else that might raise dust in the shed while its drying, and it ain’t drying fast.

Nearly done, though.

not sure if it’s cool to ask, but I’m curious what you’re charging? or is it a trade?

I’m making this table because one of the local grannies asked me to. The total materials cost was about $140, and I’m charging $200. Part of the reason that it’s such a lightly built table was because I was trying to keep the materials cost to a minimum; the buyer didn’t have a lot to spend.

Although it took me a few weeks to make, there were only a couple of days of total actual work in it, so I’m effectively getting paid about $30/day to make it. Which ain’t much when you compare it to the $120/hr I used to get for teaching neuroscience, but whatever.

When it’s something like this where I haven’t done one before, I might even be happy to do it for materials cost alone. From my perspective, that just means that I get to play with wood while someone else pays for it.

If I were making another one to put into the store or somesuch, I’d probably charge about $250 for it. Handmade timber furniture is never going to compete on price with IKEA crap.

Varnishing all done, but the tabletop has acquired a slight warp again. Probably due to the moisture content of the water-based varnish.

So, time to carefully straighten it back out again.

Clamps tightened just enough to push it back a whisker past flat, leave it there for a day or so to take a new set. Fingers crossed that the glue joints hold under the pressure. Once it’s attached to the rest of the table, the buttons should be enough to stop it warping again.

If all goes well, it should be ready to go to the new owner tomorrow.

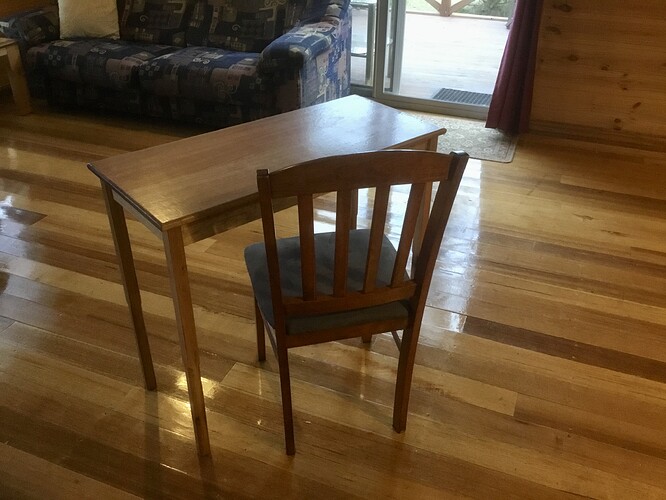

In action:

I’ve been creating online courses. I got my first one pretty much done. I’ll be adding little bits here and there, but so far, so good.

Pro Course Creation Fundamentals AKA Build Your Signature Online Course Like a Pro

I’m creating a longer course with the Build Your Signature Online Course Like a Pro name so this one serves as introductory material.

When pricing handmade goods, the general formula is 4x the price of your labor + the materials.

Wholesale price is 1/2 that.

You can always provide discounts off the ticket price. When you are starting up, you can price inexpensively, but always tell people that it’s discounted off the real price so you have room to raise prices as you get more comfortable selling.

Ros just came to collect the table.

She liked it so much, she paid me $250 instead of $200.

you earned it, man.

So, I’ve been trying to think of a name for the hanger-decos I’ve been making so I can market them and maybe make and sell some on commission.

Words that evoke wind, light, movement are what I’m looking for. Since some of the glass beads I use are prismatic, they generate pretty light dots inside my house when the sun is shining through them.

They’ve also survived the storms we’ve had recently, so I can personally attest to their durability. But durable pretty light throwing wind hangers is a bit lengthy.

Anyone out there wanna help me with this, lol? Thanks!

My friend is running this webinar tomorrow. We’d love to have you join us.

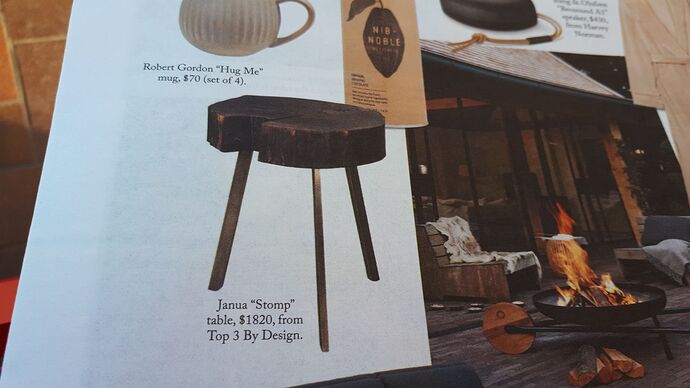

“Designer” woodcraft:

$1,820.

For a rough slice with a few spikes bashed into it, probably done on a minimally-paid production line.

Aaargh.

So, your time has a value. How much time does it take to do the project and how much would you charge an employer for that work?

I get your point, but: supply and demand also has a role to play here.

I live in an area surrounded by farmers and retired country folk. Pretty much everyone has a workshop of some sort, and apart from the big landowners most of 'em don’t have huge amounts of money.

It also isn’t that hard to find relatively affordable antique furniture around here; plenty of old farmhouses full of early Federation stuff.

Particularly with the interstate tourists gone, there is a tight limit to what the market will bear.

Which is fine; I like making things for people, and I wouldn’t expect to make a living off my woodwork even if it were priced more rationally. I’m not up to working forty hour weeks these days, let alone the 80+ it takes to make a small business successful.

People don’t compare prices as much as you think. Your prices establish your value. You can always offer discounts off that base price, but having a higher base price shows people that your work is hand crafted and special. People often use the price to determine how highly to covet something. You can give people a “good deal” and still create a way for you to move your prices upward over time as you become more confident in selling and create a market for your work.